ProductAll categories

News

As we all known, oxygen has a wide range of uses in industrial production and daily life. Air contains 21% (volume concentration) of oxygen and is the cheapest raw material for oxygen production. Therefore, oxygen is generally obtained by air separation. The cryogenic separation process is a more traditional oxygen production technology, with high oxygen purity and many product types, which is suitable for large-scale oxygen production. The principle is to liquefy the air and follow the different boiling points of oxygen and nitrogen to achieve separation.

Jianlong's JLPM series molecular sieves are mainly used for cryogenic drying of general industrial gases. The purification system in the air separation unit removes H2O and CO2, as well as natural gas and other hydrocarbon desulfurization (removal of H2S and mercaptans) and CO2.

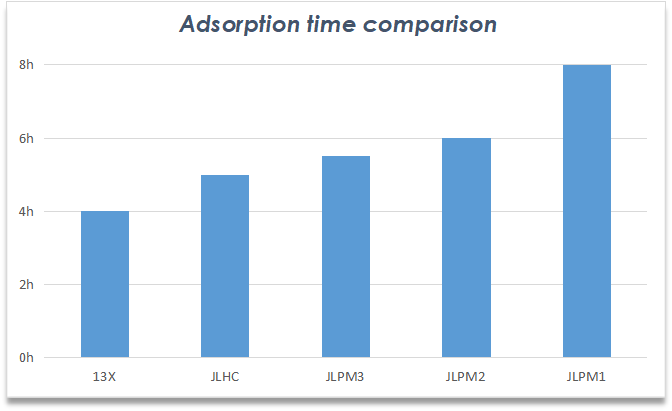

It is worth mentioning that North Copper Co. LTD, Yuanqu Smelter overhaul air separation unit using high efficiency molecular sieve, activated alumina projects use Jianlong JLPM fifth-generation cryogenic air separation molecular sieve. The equipment molecular sieve was replaced on April 12th, 2020, and it was put into operation on April 26th. From May 5th to May 8th after 72 hours of full-load operation, the CO2 at the outlet of the molecular sieve adsorber is stable at 0.2-0.3ppm, which meets the customer's requirements for CO2 ≤1ppm. The adsorption cycle is extended from 4 hours to 8 hours, so that the number of molecular sieve adsorber regenerations is reduced from 6 to 3, which not only extends the service life of equipment valves and molecular sieve, but also reduces the power load, and has a significant energy saving effect.

Jianlong fifth-generation high-performance molecular sieve JLPM is an X-crystal molecular sieve suitable for air pre-purification devices. It not only can efficiently adsorb CO2 and water vapor, but also has good dynamic characteristics and physical characteristics. Under standard process conditions, JLPM usually works synergistically with alumina and has a very high adsorption capacity for water vapor and CO2 . Instead of 13X molecular sieve, the adsorption cycle can be doubled after optimized filling.

Otherwise, The fifth-generation high-performance molecular sieve JLPM will bring multiple benefits to air separation designers and air separation operators. For the design of new air separation units, the application of JLPM can make the area of air separation smaller, thereby reducing equipment investment and operating costs; for the transformation of old equipment, the replacement of JLPM molecular sieve can reduce energy consumption and extend the service life of equipment.